INDUSTRIAL DRYERS

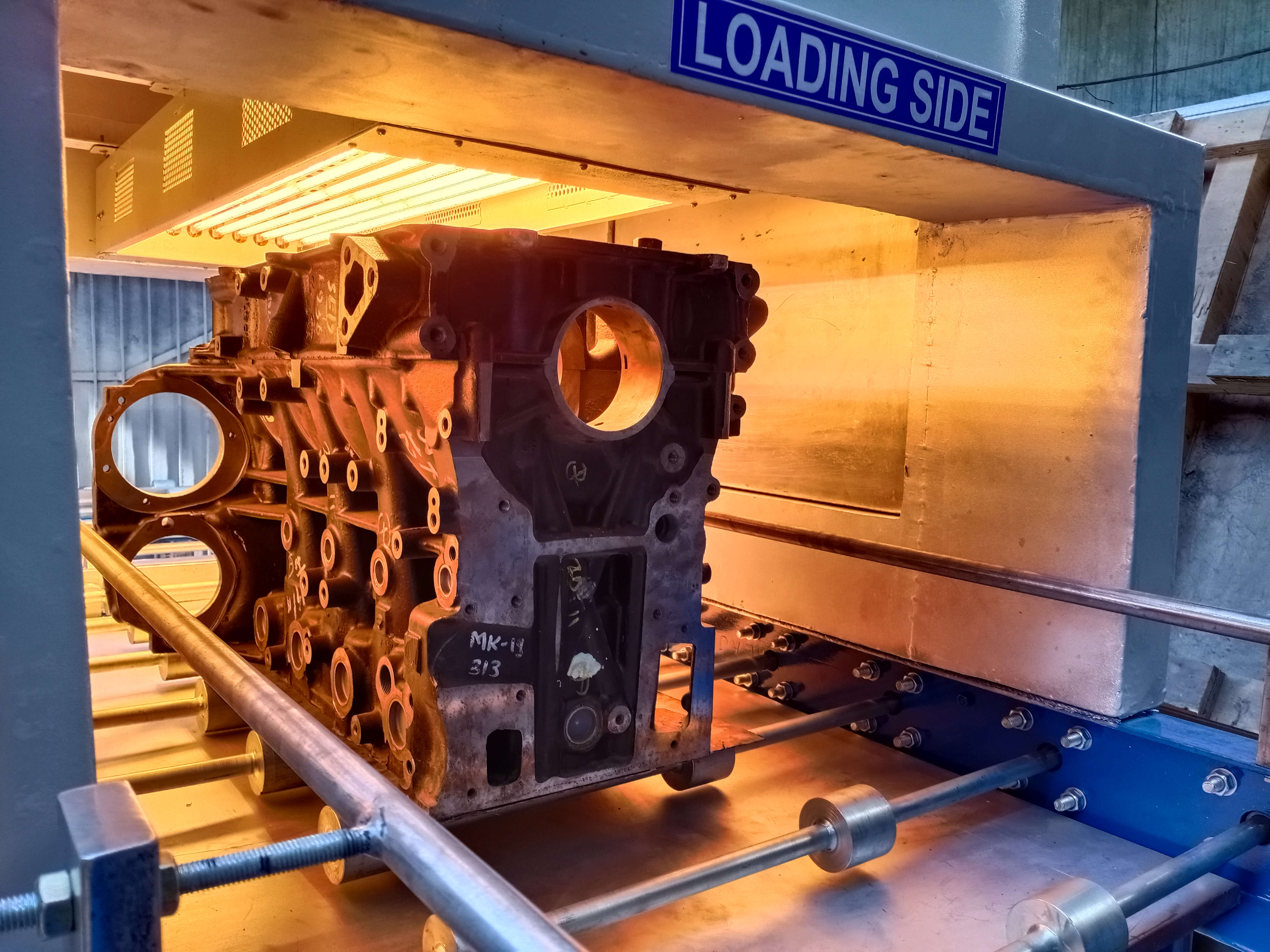

Industrial Dryer terms is referring as dynamic ovens like conveyor oven, rotary drum

oven. This Concept is widely used for production companies for multiple product requirement like

Shrinking, Annealing, Dehydration and many more with higher and continuous production rate.

Industrial Dryers construction will be in modular and manufacture on basis of tailor-made

design. We offer operating temperature range from ambient to 550°C

Product size and physical

characteristics define material type for fabrication and material handling. We offer PNG/CNG

Fired Burner, Electric Convection Heater, Infrared Heater lamps as heating source.